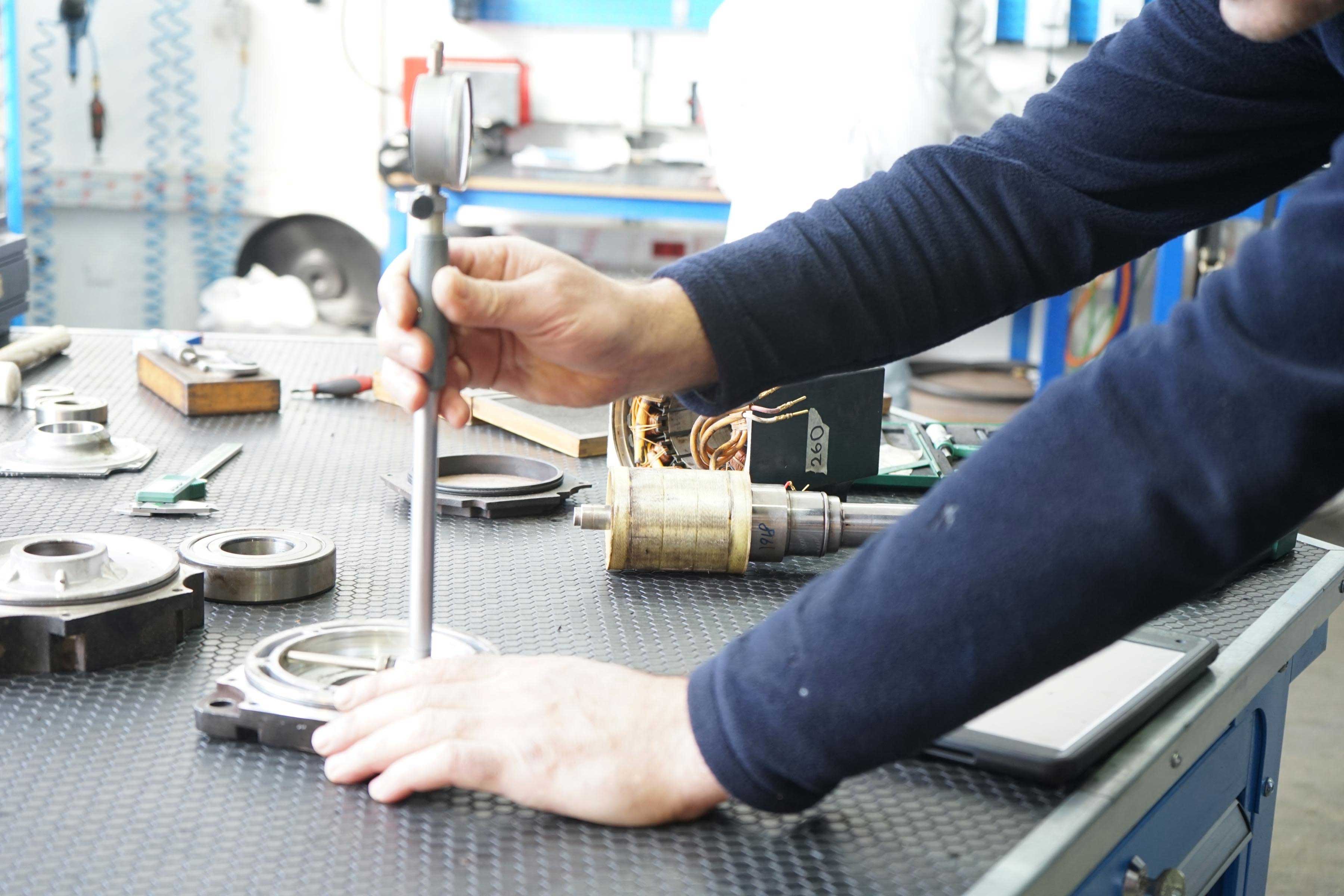

Mechanical Measurements and Interventions

The majority of servo motor failures are caused by mechanical problems. Statistics worldwide indicate that 65% of electric motor failures are due to mechanical issues. Due to the production pressure on the machines where servo motors operate, regular and periodic maintenance is often neglected. This leads to serious mechanical problems and subsequent motor failures.

If these mechanical issues are not detected in a timely manner, they can result in:

- Damage to the bearing housings in the front and rear motor covers

- Damage to the motor bearings

- Damage to the front and rear bearing housings of the rotor shaft

- Damage to the keyway in the rotor shaft

- Damage to the coupling and pulley location on the rotor shaft

These issues significantly prolong the repair and maintenance processes, making them more time-consuming and costly.

Our company has an advanced technical infrastructure that enables us to address all mechanical problems quickly and efficiently. Additionally, our in-house lathe workshop and Castolin Thermal Spray technology allow us to coat and process the rotor shaft bearing housings, as well as the motor cover bearing housings. These processes are carried out by our skilled technical personnel, enabling us to provide fast and reliable services to our customers, while also offering cost-effective solutions.